A Pakistani baked goods company gains visibility into thousands of metal assets using Confidex RFID tags; reducing audio labor costs, and enabling production improvements that help the company achieve its own sustainability goals.

Challenges:

- EBM’s sustainability initiatives require the utmost in efficiency to minimise environmental impact.

- Audits of assets used to produce and transport its products were time-consuming and costly.

- The company had limited real-time data about assets due to infrequent manual audits, resulting in inaccurate financial statements.

- In some cases, assets simply went missing.

- The lack of automated, digital data meant the company had a minimal view into production, storage and shipping activities.

Benefits:

- The RFID system leveraging Confidex RFID tags helps meet sustainability requirements by enabling efficient accurate audit counts across warehouses and production sites to reduce excess inventory and eliminate waste.

- The company has reduced labor hours previously spent on audits.

- Auditing is being conducted more often, meaning asset data is highly accurate.

- By employing RFID readers to capture data automatically, there is now potential for stock counting of raw materials as they are received and stored for production.

- The long-term benefits by tracking materials may also include process control

English Biscuit Manufacturers, (EMB), has a long history of baking his quality desserts and snacks. The Karachi, Pakistan-based company launched in 1966, to bring biscuits and pastries to a wide Middle-Eastern audience, with a focus on quality nutrition and flavour. As the company grows, it has embraced a four-part vision that includes leadership, innovation, vitality and humanity. One key initiative, however, is centred on sustainability EBM has been focusing on technologies that minimise the environmental impact of production and increase efficiency.

The necessary tools of the trade EBM are thousands of metal assets including equipment related to the production, packaging and storage of its award-winning products. Those assets are not only vital to the efficient, uninterrupted production of the company’s products, they also must be regularly maintained, inspected or replaced as needed.

Traditionally the company used a manual auditing process in which employees once a year went through the facility, physically checking each asset and documenting its location, inspection and maintenance status with pen and paper. “It was time-consuming process,” says Tahir Zaidy, COO of EBM’s integration partner ICIL Technologies (Pvt) Ltd.

To make audits more efficient, and to reduce waste resulting from a lack of visibility into production and shipping the company began looking into technology-based solutions. By digitising the identity, status and location of its assets the company not only could conduct audits more often, but the data would also be more accurate. The company chose to adopt an RFID solution with the support of several integrators, including ICIL Technologies (Pvt) Ltd. as well as Emergtech.

Ironside Slim

For the metal assets, the company required a durable RFID tag that operated reliably and effectively even in a crowded environment. They chose Confidex’s Ironside Slim RFID tags, which are applied to identify each asset, both at the production plant and administrative sites. Ironside Slime was selected for its high performance on metal fixed assets and the containers in which finished product is shipped. “Other technology, such as barcodes, need proximity and line of sight which are a hindrance to smooth tracking of assets,” Zaidy says. “On the other hand, the use of Ironside Slim tags, with their small form factor and long read range will help us in periodic physical audit of assets spread over a large geography.”

In fact, Confidex’s Ironside Family tags are optimised for metallic returnable transit items and industrial assets. Each tag comes with patented antenna design, industry-leading performance and at minimum IP68 rating durability, “Although Ironside Slim has a narrow footprint of just 21 millimetres in width, its read range extends 10 meters” said Edward Lu, Sales Director, APAC at Confidex.

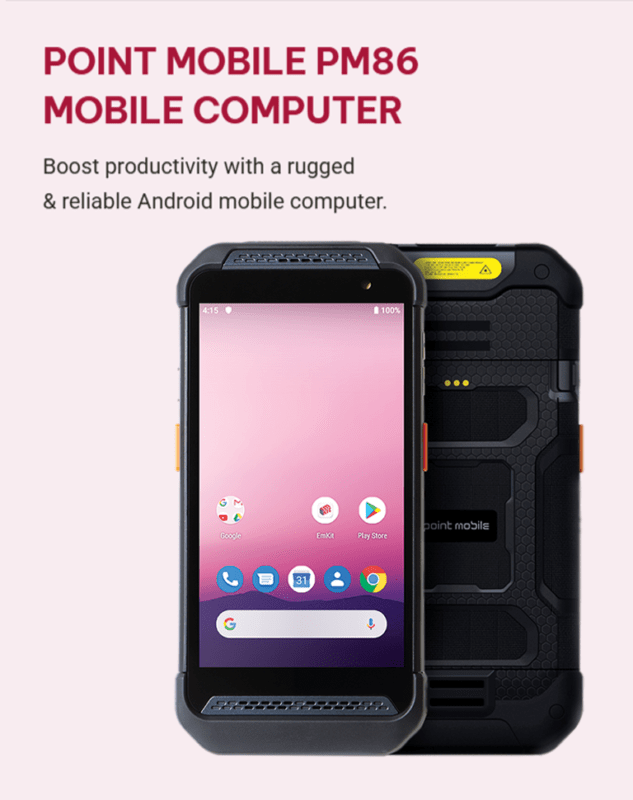

To conduct audits, EBM operators use Zebra handheld readers, employing an Android-based App. They simply carry the handheld reader through each space and automatically collect data from the Ironside Slim tags, viewing any exceptions such as missing, misplaced assets.

Results

Since the system was first deployed in 2019, the company has gained efficiency of each audit of approximately 30,000 assets. The company manages a total of 19 warehouses and two factories with administrative spaces, and assets could be identified in all of these sites.

Now the company is conducting the same audits they had conducted manually within a much shorter period of time. That means audits that used to take days, can be accomplished in a matter of hours. And because the process is more efficient, the audits can be conducted more frequently, with audits that had been undertaken annually, now possible quarterly or even every month.

The company is now focused on the benefits ahead, as it expands the applications for this technology. Such applications many include everything from providing finished product SKU data, to warehousing information to ensure prompt, accurate shipping. The system not only identifies what items are present, but also when tagged containers with loaded product must be shipped first, based on when they were filled and placed in storage. This feature ensures first in first out (FIFO) processs and helps eliminate unnecessary waste.

Further, by using the data for process flow visibility, the company hopes to yield more benefits around sustainability via long-term analysis, ultimately solving production problems and make operations more efficient.

Article credit: https://www.confidex.com/success-stories/english-biscuit-manufacturers-boosts-sustainability-efficiency-with-rfid/