During the pandemic, an e-commerce company became in high demand as the leader of Taiwan’s e-commerce industry due to its swift and efficient order fulfillment at its warehouses and prompt delivery. With an average of 1.39 million orders per month, the explosion of orders brought growth and operational challenges.

To keep up with a steep rise in order fulfillment requests, the e-commerce company focused on expanding its logistics and warehouse networks. This included 14 warehouse and distribution centers and 23 micro-fulfillment centers. This growth called for additional label printers to support operational surges with efficiency.

Challenges

When the e-commerce company’s Warehouse Management System (WMS) was built, it tied handheld and label printers from exclusive brands. This didn’t cause any issues until the coronavirus outbreak. Because the system was tied to exclusive brands, the e-commerce company could not migrate to other branded devices at will. Under the pressure of overwhelming growth in orders and 24-hour delivery, the e-commerce company faced several challenges:

- Equipment Shortage: Due to the pandemic, the exclusive mobile printer brand they’d been using faced a supply shortage. The mobile label printers ordered a year ago to fulfill operational needs were still not delivered. This hindered their ability to expand their business quickly to meet demand.

- Severe Labor Shortage:strong The pandemic worsened the labor shortage too. To counter this problem, the e-commerce company planned to increase the number of mobile printers used across its warehouses to reduce unnecessary travel to pick up labels.

- Resistance to Change: It is common for employees and e-commerce operators to be resistant to change. To ensure a smooth transition to a new system, the IT team had to find a replacement that offered an equivalent or even better user experience.

Solution

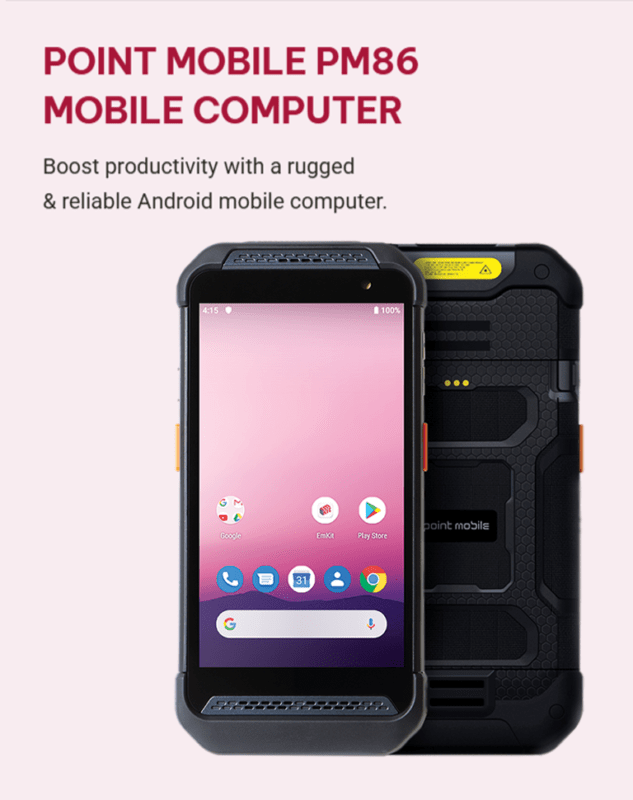

The e-commerce company called on TSC Printronix Auto ID to help solve their problem. The first priority was to overcome the WMS bundle and tie challenge to resolve printer supply shortages. The second priority was to maximize asset utilization without causing major changes to workflows and overall operations, which required new printers be easy to use and scalable for diverse applications.

Breaking System Limitations

To add more mobile printers into production, the TSC Printronix Auto ID Alpha-40L and Alpha-4L Mobile Printers had to understand the commands from the e-commerce company’s WMS and precisely proceed with all instructions. To achieve this, TSC Printronix Auto ID’s engineers studied, verified, and customized firmware to enable the Alpha-40L and Alpha-4L Mobile Printers to understand the WMS system language. Together with the existing printer language emulation function, the TSC Printronix Auto ID printers can then operate under the customer’s current WMS system.

Meeting Operational Requirements

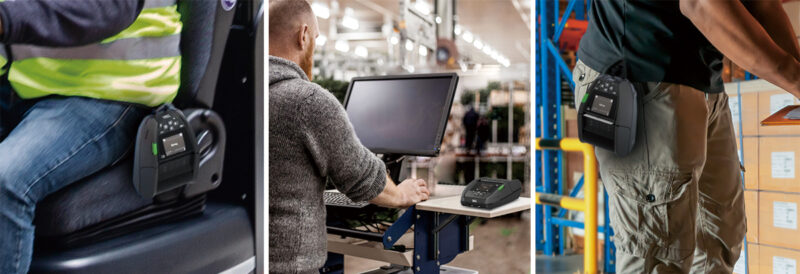

The Alpha Series Mobile Printers became forces of productivity and efficiency due to their user-friendly design. Their auto calibration feature makes print operation easy. No additional settings are required for operators after changing and installing new media rolls. Operators also favor Alpha Series Mobile Printers because they’re reliable and compact whether they’re used in a print cart or carried around. The smart battery allows it to operate with maximum productivity for a full shift, reducing process disruptions.

From IT’s point of view, the mobile printer’s full line of accessories such as shoulder straps and battery charging docks are helpful in reducing time spent managing assets, while also easing operations. Most importantly, the TSC Printronix Auto ID printers’ ability to support major printer language emulations allows label templates to remain unchanged during migration. This makes for a highly compatible and desirable solution for rapid setup.

Article Source: TSC