RFID system increases pool visibility, allows efficient asset utilization and allows exact customer billing by actual usage.

Application

- Logistics And RTI Operation

Challenges

- How to efficiently track the IBC’s at 400 warehouses all around the world and in customer locations

- Room for improvement in asset utilization

Benefits

- Increased administration efficiency

- Increased pool utilization

- Better tracking resulting smaller risk for loss and theft

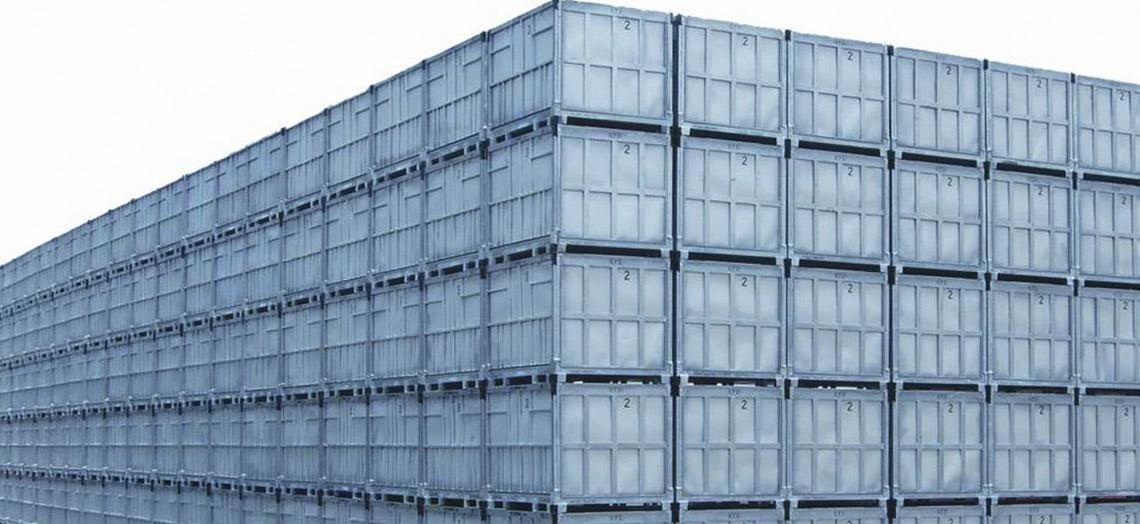

The world’s largest metal intermediate bulk, IBC, container provider, is operating globally through over 400 warehouses and supplying returnable transit item services for automotive, tire, chemical and food industries. In total, IBC are used in over 70 countries and more than 5000 locations worldwide.

Managing the pool of 2.6 million IBCs with such a wide operational coverage requires close monitoring of what amount is available in which depot, which quantity was shipped to the customer, what quantity returned and what is the condition of the IBCs. The container provider had implemented a barcode system for being able to track the containers better, however, the barcode readability and reliability were decreased due to dirt and wear.

The RFID system at IBC is the base for getting various business benefits. Implemented by Confidex partner, the RFID system allows the container provider to reduce manual administration of the pool by increased automation. IBC is also now able to have visibility over its 400 warehouses and get exact information of container quantity and in that way optimize the pool usage. Enhanced tracking makes it possible to decrease asset loss and cost that is caused by missed expensive steel containers. In addition, by being able to track more accurately and efficiently what is shipped and when the RFID system allows billing the customer based on the very exact usage of IBCs. By tagging its entire fleet of IBCs, it also offers its customers to build new ways for automating raw material receiving processes, as an example.

What’s being tagged?

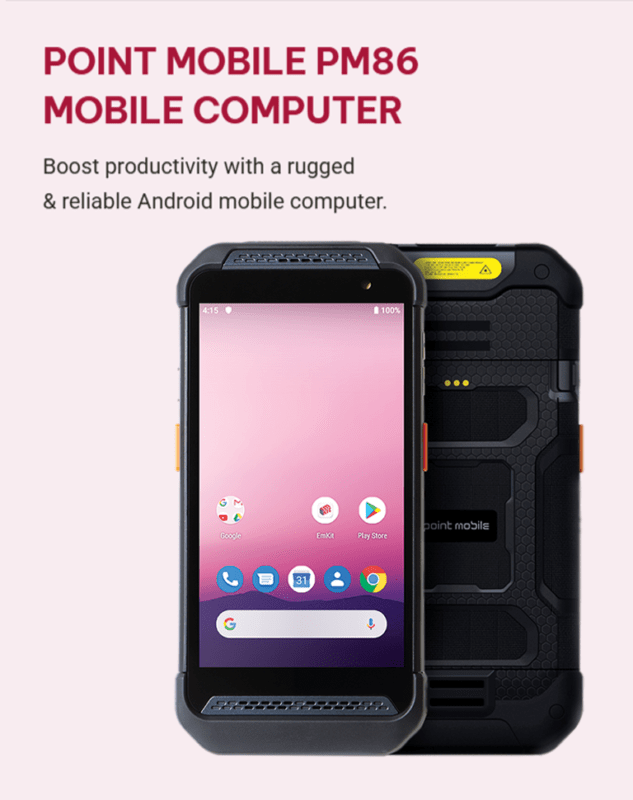

The intermediate bulk containers are made of durable galvanized steel for maximum durability when the IBCs are used for carrying e.g. liquids, rubber or car components. IBCs are handled roughly and in various weather and environmental conditions. Due to the foldable structure of an IBC, there are not many possible surfaces for attaching an RFID tag. Because of this, besides being mechanically durable, the RFID tag must flexibly and efficiently perform even though not placed in the optimum location. Confidex Ironside Slim™ is designed specifically for tracking of various metal containers and cages and the tag was selected by Goodpack. Ironside Slim tags are attached mechanically to the IBC and they are being identified with both RFID gates and hand-held RFID readers.

Article Credit – https://www.confidex.com/success-stories/intermediate-bulk-containers-are-being-identified-with-rfid-at-goodpack/