Trusted Guidance from Singapore’s Barcode & RFID Experts

This comprehensive guide is brought to you by Barcode.com.sg. Since 2004, we have been the trusted partner for businesses across Singapore, providing cutting-edge barcode, RFID, and auto-ID solutions. With over two decades of experience, we have helped more than 10,000 businesses—from SMEs to multinational corporations—streamline their operations, improve inventory accuracy, and boost productivity.

The insights in this guide are based on our hands-on experience implementing real-world tracking systems in the unique context of Singapore’s retail, logistics, warehousing, and manufacturing sectors. Our team of certified experts is committed to providing accurate, practical, and authoritative information to help you make the right technology decisions for your business.

Executive Summary: RFID in a Nutshell

What is RFID? Radio Frequency Identification (RFID) is a technology that uses radio waves to automatically identify and track objects wirelessly, without needing a direct line of sight.

Key Takeaways:

- Core Difference from Barcodes: Unlike barcodes that must be seen to be scanned, RFID tags can be read through packaging and from a distance, enabling rapid bulk scanning of hundreds of items at once.

- Primary Benefit: It provides real-time, accurate visibility into inventory, assets, and shipments, drastically reducing manual counting errors and saving time.

- Main Types: Passive RFID (low-cost, no battery, for general inventory), Active RFID (long-range with a battery, for tracking high-value assets), and Semi-Passive (a hybrid with sensor capabilities).

- Common Use Cases: Revolutionizing inventory management in retail, tracking medical equipment in healthcare, ensuring supply chain visibility in logistics, and securing facilities with access control.

- Bottom Line for Singapore Businesses: RFID offers a proven return on investment (ROI) by improving inventory accuracy from ~70% to over 99%, reducing labor costs, and preventing stockouts, making it a strategic upgrade for any data-driven operation.

In today’s fast-paced business world, organizations are always looking for ways to improve operations, reduce costs, and increase accuracy. Radio frequency identification technology, or RFID, has become a powerful solution. The global RFID market is expected to reach $26.66 billion by 2032. Unlike traditional methods, RFID tags provide unparalleled visibility into inventory, assets, and operations through wireless data capture and real-time tracking. Their low cost has made RFID accessible to businesses of all sizes across many industries.

RFID tags play a crucial role in cargo tracking applications, enabling real-time monitoring of shipments and streamlining operations within distribution centers by automating data collection and improving inventory management.

This guide covers everything you need to know about RFID technology—from its basic components to choosing the right solution for your needs. Whether managing retail inventory, tracking medical equipment, or optimizing supply chains, RFID tags can revolutionize how you collect data and monitor assets. This leads to more efficient business processes and improved productivity.

Introduction to Radio Frequency Identification

Radio Frequency Identification (RFID) is a cutting-edge technology that uses radio waves to automatically identify and track objects. At its core, RFID technology relies on a small radio transponder, a radio receiver, and a transmitter to facilitate seamless data exchange. When an RFID reader emits a specific radio frequency, it activates the transponder, which then transmits digital data—such as an inventory number or product code—back to the reader. This process enables rapid and contactless identification, making RFID a powerful tool for inventory management and data collection.

RFID technology is widely used across industries like retail, healthcare, and logistics, where accurate tracking and efficient operations are essential. Unlike traditional identification methods, RFID does not require direct line of sight, allowing for faster and more flexible data capture. The ability to transmit and receive data over various frequencies makes RFID adaptable to different environments and applications, from tracking retail inventory to managing assets in large warehouses. As a result, RFID has become an integral part of modern business operations, driving increased efficiency and accuracy in data-driven processes.

RFID Tags vs. Traditional Identification: Why Switch?

RFID tags are small electronic devices with microchips and antennas that store and wirelessly transmit digital data. RFID tags are used to automatically identify items by transmitting the data stored on each tag to an RFID reader. Both RFID tags and barcodes require a device—an RFID reader or barcode scanner—to read data. However, RFID tags communicate with readers using electromagnetic energy, allowing automated data collection without direct contact or line of sight.

Compared to barcodes, RFID technology offers clear advantages. Barcodes are limited to one-dimensional data and need line-of-sight scanning, while RFID tags provide greater efficiency, higher data capacity, and can be read without line of sight. The data stored on RFID tags, such as Electronic Product Codes (EPCs), enables more detailed identification and tracking of individual items by linking them to global databases, which is not possible with traditional barcodes. This makes RFID a complementary or alternative identification method.

| Feature | RFID Tags | Barcodes | QR Codes |

| Read Range | Up to 10+ meters (UHF) | Contact required | Contact required |

| Bulk Reading | Hundreds simultaneously | One at a time | One at a time |

| Line of Sight | Not required | Required | Required |

| Data Storage | 96-bit to 8KB (data stored can include unique identifiers for each item) | Limited serial number | Up to 3KB |

| Environmental Resistance | High (depending on substrate) | Moderate | Moderate |

| Cost per Tag | $0.10 – $100+ | $0.01 – $0.05 | $0.01 – $0.05 |

Key benefits driving RFID adoption include:

- No Line of Sight Needed: Unlike barcodes that require direct scanning, RFID tags can be read through packaging, containers, or embedded within products. Barcode scanners need manual positioning and line-of-sight, making the process slower and more labor-intensive. RFID enables automated inventory counts and asset tracking without manual handling.

- Bulk Reading: An RFID reader can identify hundreds of tagged items at once within its range, dramatically reducing labor costs and speeding up inventory audits, receiving, and cycle counts.

- Extended Range: UHF RFID tags can be read from over 10 meters away, and some active tags reach over 100 meters. This long range allows automated tracking of vehicles, containers, and high-value assets across large facilities.

- Real-World ROI: Although initial costs are higher, businesses often see returns within 12-18 months. For example, a major retailer improved inventory accuracy from 70% to 99%, reduced out-of-stock by 30%, and increased sales by 2-3% after adopting item-level RFID tagging. RFID automation saves time, allowing employees to focus more on customer service.

Industry data shows growing adoption: 61% of retailers are increasing RFID investments, with around 50 billion RFID chips sold in 2024. This reflects RFID’s proven value across many sectors.

RFID vs Barcode: Cost, Accuracy & Use Cases

| Factor | RFID | Barcode |

| Line of sight required | No | Yes |

| Reading method | Bulk (hundreds at once) | One at a time |

| Typical accuracy | 95–99%+ | 85–95% |

| Labor requirement | Low | High |

| Cost per tag | $0.10 – $100+ (depending on type) | $0.01 – $0.05 |

| Infrastructure cost | Higher upfront | Low |

| Speed | Very fast | Moderate |

| Best for | Warehouses, logistics, asset tracking | Retail checkout, basic inventory |

| Scalability | Excellent for large operations | Limited at scale |

| ROI timeline | 12–18 months (typical) | Immediate but limited gains |

Bottom-Line Guidance:

- Choose RFID if you need automation, speed, and real-time inventory visibility.

- Choose barcodes if cost is the primary concern and scanning volume is low.

Is RFID better than barcodes?

RFID is better than barcodes in environments that require speed, automation, and high accuracy. RFID allows bulk scanning without line of sight, reducing labor and errors. Barcodes are more cost-effective for basic tracking, but RFID delivers greater efficiency and real-time visibility in warehouses, logistics, and large retail operations.

When should you use RFID instead of barcodes?

You should use RFID when manual barcode scanning slows operations, inventory accuracy is critical, or items need to be tracked automatically in real time. RFID is commonly used in warehouses, distribution centers, and supply chains where high-volume movement and minimal human intervention are required.

Understanding RFID Tag Technology

RFID works through electromagnetic communication between a tag and a reader. When an RFID reader emits radio waves, nearby passive tags capture this energy to power their microchip and send stored data back. In some frequency bands, like HF RFID, magnetic fields generated by coil antennas ensure reliable communication, especially at close range. This wireless exchange happens in milliseconds, enabling fast automated identification.

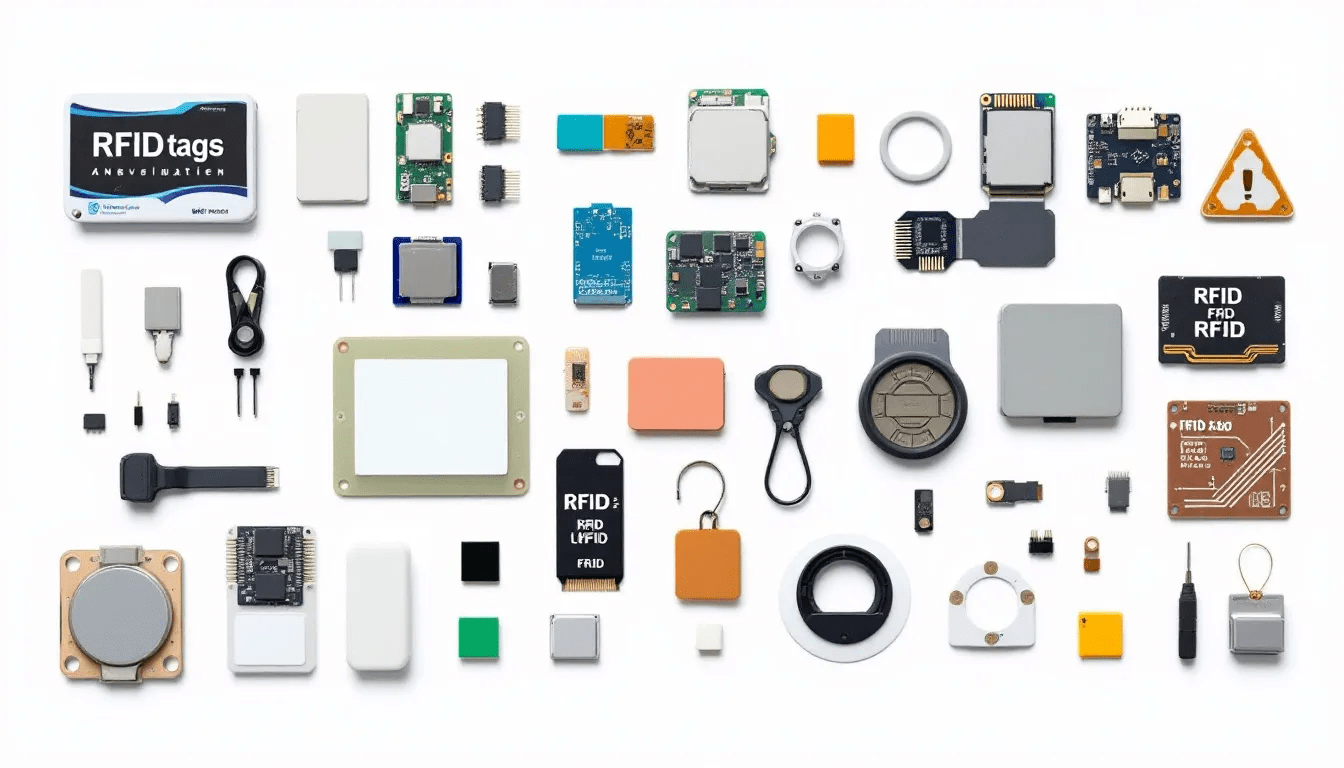

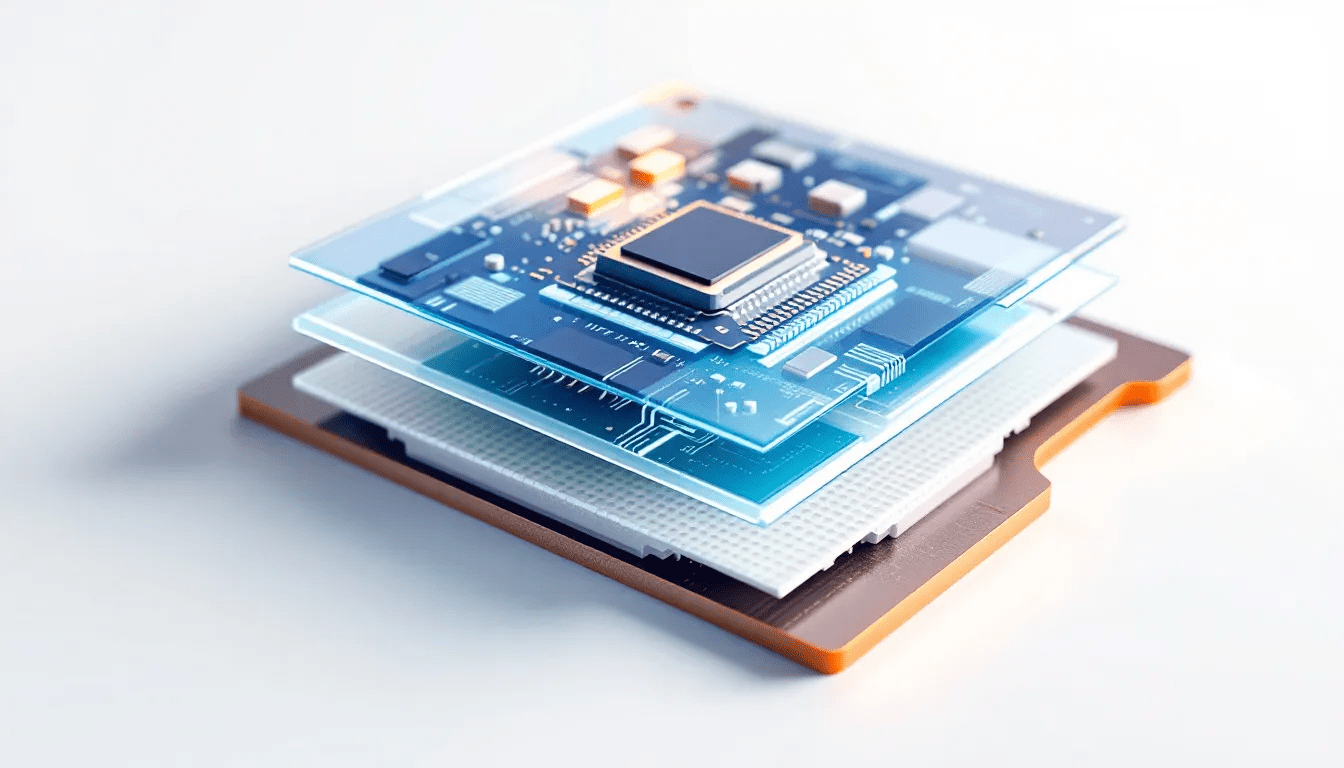

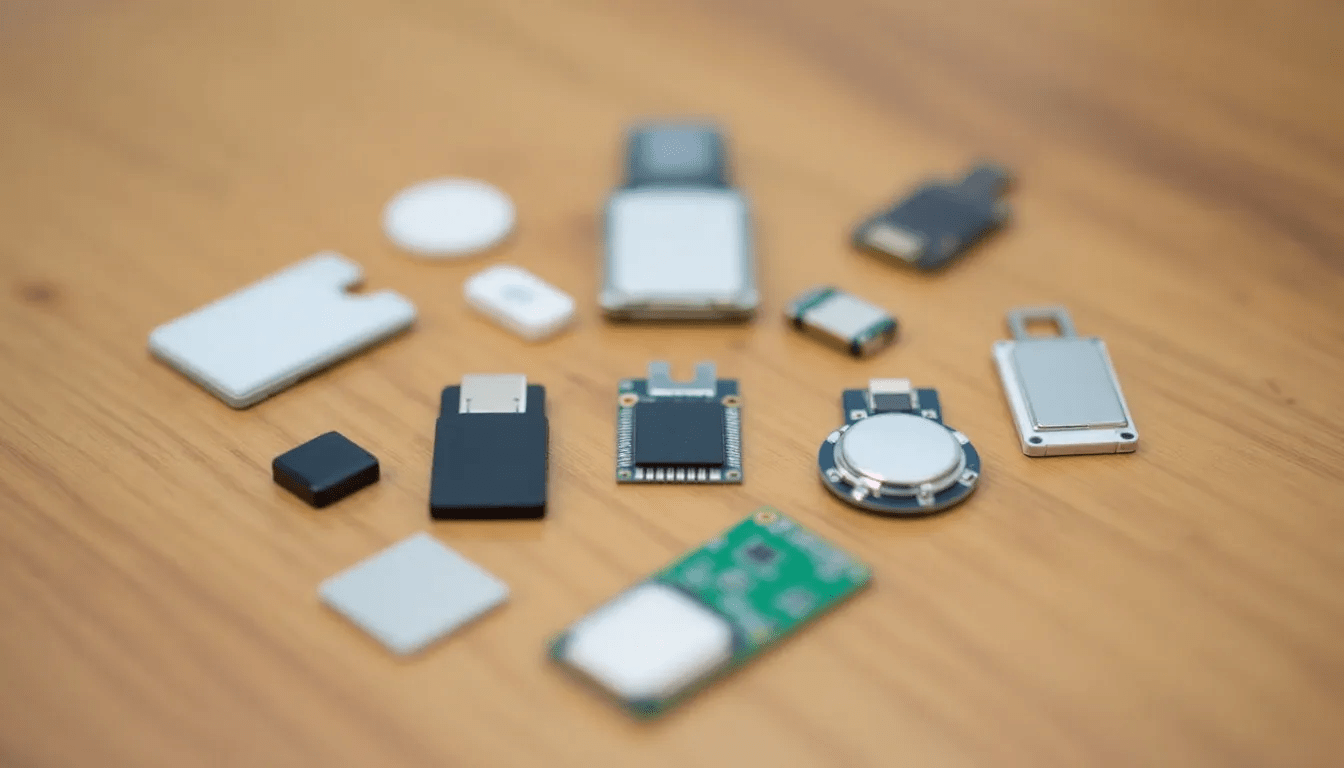

An RFID system consists of three main components: RFID tags, readers, and software, each vital for data collection and communication. RFID tags are made out of three pieces: a chip, an antenna, and a substrate.

The Microchip: Data Storage

The microchip stores unique identification information and often additional product details. Data on RFID tags typically includes product codes, serial numbers, and the Electronic Product Code (EPC), which identifies products globally. The data stored on RFID tags is crucial for accurate identification and tracking, as it links each item to a global database and supports functions like collision detection and tag singulation during RFID reading processes. Modern RFID chips have memory capacities from 96-bit identifiers to 8KB, depending on use. Using RFID can trigger automatic reorders based on live inventory data.

Most supply chain applications use the EPC standard, a 96-bit code containing manufacturer ID, product class, and unique serial number, enabling precise tracking in distribution.

RFID tags are either:

- Read-only, with fixed info programmed during manufacturing (e.g., serial numbers), ideal for simple identification.

- Read/write, allowing updates during the tag’s life, useful for tracking manufacturing status, quality control, or maintenance.

Advanced RFID chips include encryption and security features like password protection and kill switches to prevent unauthorized access or counterfeiting.

The Antenna: Communication Interface

The antenna affects read range and performance. Designs vary by frequency and application, with ongoing miniaturization down to 0.05mm for special uses.

- Low frequency antennas (125-134 kHz) use coiled wires, perform well near metal and liquids, and have short read ranges.

- High frequency antennas (13.56 MHz) use loops or spirals for medium-range (up to 1 meter), suited for access control and payments.

- Ultra high frequency antennas (860-960 MHz) use dipole or patch designs for long range (10+ meters), enabling bulk reading in warehouses.

Antenna performance depends on tag orientation to the reader. Designs with multiple elements or circular polarization reduce sensitivity to orientation, improving reliability.

The Substrate: Physical Base

The substrate holds the microchip and antenna, protecting them from environment. Materials depend on application, attachment, and durability needs. Environmental conditions such as temperature and humidity can significantly impact the performance and durability of RFID tags, so choosing the right substrate is crucial for reliable operation.

- Paper substrates are low cost for disposable retail tags, suitable indoors but less resistant to moisture or heat.

- Plastic substrates offer durability and chemical resistance for industrial uses, flexible for curved surfaces.

- Fabric substrates allow integration into clothing, surviving laundering while maintaining performance.

- Ceramic/metal substrates provide robust protection in harsh environments, though costlier.

Attachment methods include adhesives, thermal bonding, mechanical fasteners, or molded designs, balancing secure mounting and antenna performance.

How RFID Tags Work

RFID tags, often referred to as transponders, are compact devices designed to store and transmit data to RFID readers. Each tag is built with three essential components: an antenna for receiving and sending radio waves, a microchip for storing digital information, and a substrate that holds everything together. These tags come in several types, including passive tags, active tags, and battery-assisted passive (BAP) tags, each suited to different applications.

Passive tags are powered solely by the electromagnetic energy emitted from RFID readers. When a reader sends out radio waves, the passive tag’s antenna captures this energy, activating the microchip to send back stored data such as a unique serial number, stock number, or batch information. Active tags, on the other hand, contain their own battery, allowing them to transmit signals over longer distances and at regular intervals, making them ideal for real time tracking of high-value assets. Battery-assisted passive tags combine features of both, using a battery to boost performance while still relying on the reader’s signal for communication.

When an RFID reader’s radio waves trigger the tag to respond with its stored data. This exchange happens in milliseconds, enabling rapid identification and data collection for inventory management, asset tracking, and more. The versatility of RFID tags—whether passive, active, or BAP—makes them indispensable tools for companies seeking efficient, automated solutions for tracking and managing data across a wide range of devices and environments.

Types of RFID Tags and Choosing the Right One

Choosing the right RFID tag depends on application needs, environment, performance, and budget. The three main types each have pros and cons:

Passive RFID Tags: The Workhorse

Passive tags have no internal power and rely on energy from the reader to operate. A passive RFID tag is a type of RFID technology that functions without its own power source and can be read at varying ranges depending on frequency, which raises privacy and security considerations. They are widely used due to low cost and long life.

- Read ranges:- Low frequency: ~10 cm

- High frequency: ~1 meter

- Ultra high frequency: ~10 meters

Passive tags are common in loyalty cards, access control, and inventory tracking. They last over 10 years, cost from $0.10 to $2.00 depending on features.

Limitations include reduced performance near metal or liquids and shorter range with smaller tag sizes.

Active RFID Tags: Long Range

Active tags have batteries powering the chip and transmission, enabling longer ranges and sensor integration.

- Battery life: 3-7 years

- Read range: 10-100+ meters

- Cost: $20-$100+

Active tags suit vehicle tracking, cargo monitoring, and real-time asset tracking. They can include sensors for temperature, humidity, or GPS.

Higher cost and maintenance (battery replacement) limit their use to high-value assets.

Semi-Passive (Battery-Assisted Passive) Tags

These combine passive communication with a battery powering the chip, improving sensitivity and range.

- Cost: $3-$15

- Read range: 15-30 meters

- Features: Sensor support for temperature, humidity, shock

Semi-passive tags offer better performance than passive at lower cost than active, useful in pharmaceuticals, food safety, and high-value inventory.

Battery replacement is needed but less frequent than active tags.

Common Applications of RFID Tags

RFID technology improves accuracy, reduces labor, and enhances supply chain visibility across industries. In logistics, RFID is employed for yard management and to track shipments within distribution centers, ensuring smoother operations and better inventory control. Additionally, RFID can track asset movement and integrate with sales data to provide insights into shrinkage patterns.

Retail and Inventory

Retail leads RFID growth, with mandates from major retailers driving adoption. For example, Zara tracks over 5 billion items annually, achieving real-time stock visibility and reducing out-of-stock by 30%. Some retailers use RFID systems for self-checkout options, streamlining the shopping process and reducing wait times. Retailers also use RFID technology to improve the shopping experiences for omnichannel shoppers.

Benefits include:

- Inventory accuracy from 70% to 99%+

- Shrinkage reduction by 15-25%

- Labor savings of 80% on inventory counts

- Sales increases of 2-3%

Mobile devices and handheld readers help store associates locate items, verify prices, and process sales. RFID allows bulk reading of racks, speeding inventory from hours to minutes. Additionally, RFID helps in preventing theft by using electronic article surveillance (EAS) systems, which alert staff to unauthorized removals. RFID technology enhances customer experiences by providing personalized interactions in stores and is essential for label printing.

Healthcare and Patient Safety

Hospitals use RFID to track patients, prevent medication errors, and monitor medical equipment. In addition to these uses, RFID systems are typically employed for workflow and inventory management, ensuring that critical supplies and equipment are always available when needed.

- RFID wristbands verify patient identity and dosing, preventing 80% of medication errors.

- Equipment tracking improves utilization by 20-30%, saving $50,000+ annually.

- Blood bank management uses RFID to monitor storage conditions and inventory.

Mobile readers enable instant equipment location and status checks, integrating with hospital systems for compliance.

Manufacturing and Supply Chain

Manufacturers use RFID for work-in-progress tracking, quality control, and traceability.

- Automotive assembly lines embed tags to monitor progress and quality.

- Logistics providers automate receiving and shipping with UHF RFID, cutting processing time by 60%. RFID tags are also widely used in cargo tracking applications, enabling real-time monitoring and management of shipments throughout the supply chain.

Benefits include:

- Real-time production visibility

- Quality traceability for recalls

- Inventory accuracy improvements

- Counterfeit prevention in pharmaceuticals and luxury goods

Perishable goods use sensor-enabled RFID to monitor temperature during transport and storage.

Access Control and Security

RFID replaces traditional key cards with encrypted badges for secure access.

- Employee badges, including RFID badges, are used for employee access and movement tracking in secure facilities, helping to restrict unauthorized personnel and improve workflow management.

- Systems integrate biometrics for multi-factor authentication.

Other uses include vehicle access, event management, and cashless payments.

Security policies include time/location restrictions and visitor management. However, organizations must address security issues like unauthorized access and data breaches by implementing strong protections.

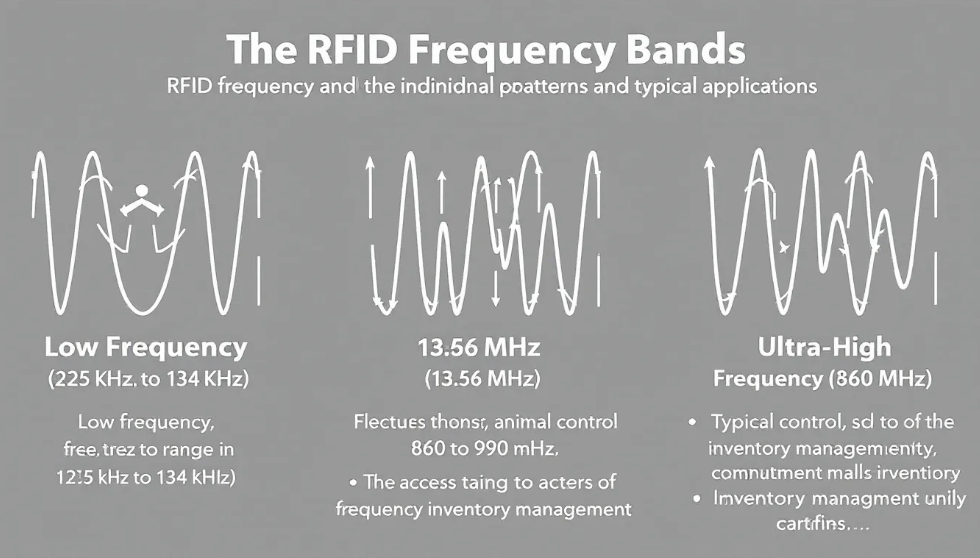

RFID Frequency Bands and Standards

RFID operates in several frequency bands, each with unique features.

Low Frequency (LF): 125-134 kHz

- Short read range (~10cm)

- Reliable near metal and liquids

- Used for animal ID and close-proximity access control

High Frequency (HF): 13.56 MHz

- Medium range (up to 1 meter)

- Supports NFC for mobile payments, allowing users to make contactless transactions with a mobile phone using RFID technology

- Used in libraries, transit passes, and smart cards

Ultra High Frequency (UHF): 860-960 MHz

- Long read range (3-10 meters, more with special setups)

- Supports bulk reading of hundreds of tags

- Drives supply chain and logistics applications

Global standards like EPC Gen2 (ISO 18000-6C) ensure interoperability. Regional frequency regulations require compliance for global use, especially for solutions such as barcode tracking software & inventory management systems.

Benefits of Implementing RFID

Implementing RFID technology offers a host of advantages for businesses aiming to streamline operations and boost productivity. One of the most significant benefits is improved inventory management. RFID enables real-time tracking and monitoring of inventory levels, reducing the risk of stockouts and overstocking, especially when paired with tools like a barcode scanner stand. This level of visibility ensures that companies can respond quickly to changes in demand and maintain optimal inventory levels.

RFID also enhances supply chain visibility by allowing companies to track products and assets throughout the entire supply chain, from manufacturing to delivery. This transparency leads to better decision-making and more efficient supply chain management. By automating data collection, RFID reduces labor costs and minimizes human error, freeing up staff to focus on higher-value tasks.

Asset tracking is another key benefit, as RFID technology makes it easy to monitor the location and status of equipment, tools, and other valuable assets. Enhanced access control and the ability to monitor sensitive data further strengthen security across operations. Overall, RFID technology delivers a wide range of benefits—including increased efficiency, reduced costs, and improved productivity—that help companies stay competitive in today’s fast-paced business environment.

Choosing the Right RFID Tags for Your Business

Selecting RFID solutions requires evaluating technical needs, vendor quality, and integration plans.

Vendor Selection

Look for vendors with:

- ARC certification for tag performance

- ISO 9001 quality standards

- Strong technical support

- Financial stability for long-term service

Leading suppliers include Avery Dennison, UPM Raflatac, and SML Group.

Cost and Volume Pricing

Costs include tags, readers, software, integration, and support.

- Basic passive tags: $0.10-$0.50 in high volumes

- Specialized passive tags: up to $2.00

- Semi-passive tags: $3-$15

- Active tags: $20-$100+

Volume discounts are common; infrastructure costs often dominate large projects.

Integration

Integrate readers with ERP, WMS, and inventory systems. Consider communication protocols, data formatting, middleware, and database updates.

Mobile and fixed readers serve different needs; proper antenna placement and testing are crucial.

Pilot programs validate performance and ROI before full deployment.

Conclusion: Transform Your Operations with RFID

RFID has evolved into a vital tool for digital transformation. With market growth projected to $26.66 billion by 2032, early adopters gain competitive advantages through automation, accuracy, and real-time visibility.

Benefits include inventory accuracy improvements from 70% to over 99%, labor savings, and proactive decision-making. These translate to better customer satisfaction and optimized operations.

Implementation steps:

- Assess current processes and benefits

- Run pilot programs to test RFID

- Choose qualified vendors

- Integrate RFID data with existing systems

- Train staff and manage change

- Monitor and expand successful uses

Implementing RFID can improve customer satisfaction by ensuring accurate, on-time shipments.

Future trends include integration with IoT, AI analytics, and blockchain for supply chain transparency. Advances in chip miniaturization, battery life, and cordless security address privacy concerns.

Whether for inventory, asset tracking, or access control, RFID tags offer proven solutions to improve efficiency and visibility. Falling tag costs and strong ROI make RFID a strategic choice for businesses today.

RFID Readers and Their Role

RFID readers connect RFID tags to digital systems. Also called interrogators, they emit electromagnetic energy to activate tags and capture their data. This enables automatic identification and streamlined operations.

Types include:

- Fixed readers: Installed at entrances, conveyor belts, or dock doors for continuous monitoring and supply chain visibility.

- Handheld readers: Portable for inventory, asset tracking, and spot checks, reducing labor and boosting productivity.

- Mobile readers: Integrated into smartphones and tablets for flexible, on-the-go data collection.

When a tag‘s enters a reader‘s range, the reader energizes it, and the tag sends back digital data like unique IDs or product info. This data is sent to computer systems for processing and integration with inventory or supply chain software.

Readers operate on LF, HF, and UHF frequencies, chosen based on application, tag type, and environment.

Many readers can also write data to tags, supporting dynamic applications like updating asset status or managing sensitive data throughout the supply chain.

Frequently Asked Questions (FAQs)

What is an RFID tag?

An RFID tag is a small electronic device that uses radio waves to store and transmit data to an RFID scanner or reader. Each tag contains a microchip and an antenna, allowing items to be identified and tracked wirelessly without line of sight. RFID tags are commonly used for inventory management, asset tracking, and supply chain visibility.

RFID vs barcode tracking software: which is better?

RFID tracking software offers higher accuracy and automation than barcode tracking software because RFID tags can be read in bulk without line of sight. Barcode systems are lower cost and suitable for basic tracking, while RFID systems are better for high-volume, fast-moving environments where real-time visibility, reduced labor, and higher accuracy are required.

When should businesses switch from barcodes to RFID?

Businesses should consider switching from barcodes to RFID when manual scanning becomes time-consuming, inventory accuracy is below acceptable levels, or real-time tracking is required. Companies operating warehouses, logistics hubs, or large retail environments often adopt RFID when they need faster inventory counts, reduced labor costs, and improved operational visibility.

How are RFID scanners used in warehouse operations?

RFID scanners are used in warehouses to automatically read tagged items during receiving, storage, picking, and shipping processes. Fixed RFID scanners can track goods moving through dock doors or conveyors, while handheld scanners enable fast cycle counts and asset location. This reduces manual scanning, improves accuracy, and speeds up warehouse workflows.

What RFID solutions are suitable for warehouses in Singapore?

RFID solutions for Singapore warehouses typically include UHF RFID tags, fixed and handheld RFID scanners, and software integrated with inventory or warehouse management systems. These solutions help businesses improve inventory accuracy, reduce labor costs, and comply with operational efficiency standards common in Singapore’s logistics and supply chain environments.