How smaller RFID printers equate to a bigger ROI for many of your RFID labelling workflows

RFID tagging is growing in popularity across many sectors as organisations seek ways to better track and trace inventory assets.

High-value goods such as industrial equipment, IT assets, returnable containers, pallets, packages, patient wristbands and even airline passenger baggage can be better monitored and easily located with an RFID tag than a barcode-only label, as can pallets and even individual items on store shelves.

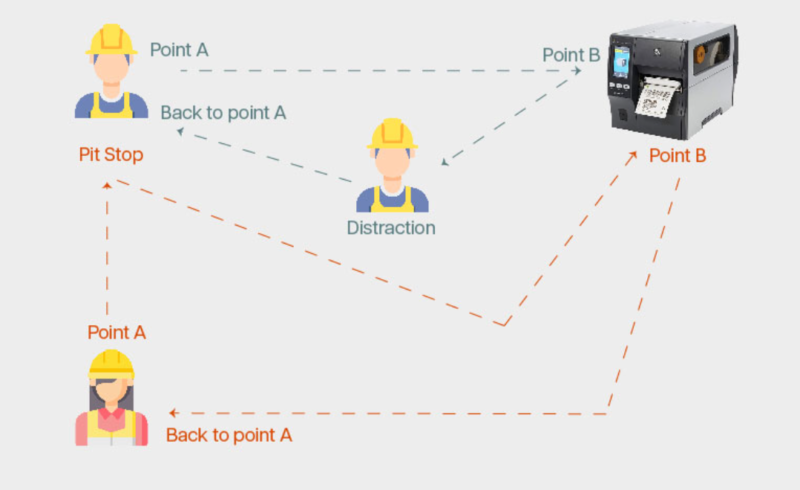

Yet, most RFID label printers are stationary printers that sit on top of a desk inside the four walls of a facility

That means the field-based workers must either batch print labels prior to heading out on their route (assuming they know which assets need to be tagged that day) or they must frequently travel to and from a printer workstation to print labels when needed.

Such movements are very disruptive to workflows and productivity.

Either grab the wrong tag, tag the wrong item or forgot to retrieve the tag along the way

The odds of those are high whenever workers have to walk away from the point of application to retrieve an RFID tag off a shared desktop/industrial printer.

A solution for workers

Therefore, workers who need to print RFID labels to do their job and do not have constant arms-length-type access to a desktop RFID printer really should be given a lightweight mobile RFID printer to carry with them everywhere they go.

Suitable for workers (not limited to) that are responsible for:

- Click & collect label printing

- Pallet labelling & tagging

- Pharmacy inventory management

- Medical specimens collection & transportation

- Parts tracking

- Supply chain traceability

Thanks to a little innovation and a lot of smart engineering, workers can now attached a portable RFID label printer to their belt, or wear it as a sling.

Article Credit: Zebra Technologies