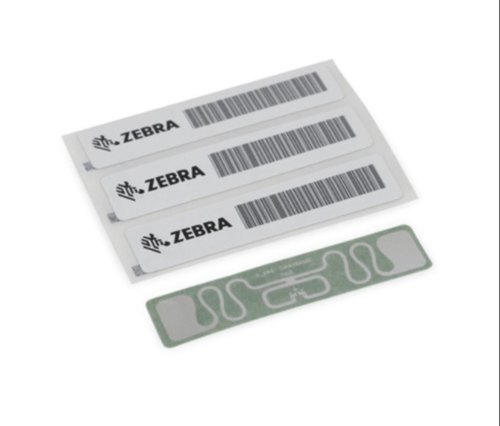

RFID (radio frequency identification) solutions can deliver transformative insights into operations, workflows and asset utilization. But an RFID solution can’t provide optimized visibility without high-performing RFID labels and inlays. The label with the RFID inlay enables the RFID reader to gather information on the asset, providing a digital voice to it. Without it, you can’t identify or track the asset.

RFID labels are the critical components that ensure assets are accurately identified and tracked, allowing asset-related data to be properly aggregated for analysis. They provide vital data points for transportation and logistics, manufacturing, healthcare and other industries, and can benefit businesses in every vertical segment.

There are, however, many potential problems that can compromise RFID labels. Challenging surface materials (e.g. metals, rough textures, dirt) or curved shapes, underperforming adhesives, poor-quality thermal printing and more can cause RFID labels to unstick and fall off or become unreadable. The results directly impair asset tracking and cause errors in data aggregation, leaving enterprises without true real-time visibility into their operations. That is why you must be as thorough in your evaluation of RFID label and inlay quality as you would for an RFID reader.

Selecting the Right RFID Labels

There are several factors to consider when selecting RFID labels, but these three are the most important:

- Inlay Size. A larger RFID inlay gives you longer read ranges.

- Reader Type. Handheld, fixed and overhead readers often perform differently and serve different use cases.

- Material Surface and Environment. Consider the surface of the material – such as corrugate box, wood, glass, plastic, metal, etc. – as well as how densely items are stacked or what is contained within the boxes. If the signal must pass through objects that attenuate the signal, the read range is diminished.

RFID solutions require significant time and cost investments. If your enterprise is investing in RFID without high-quality, high-performing labels and inlays, the return on investment (ROI) may be greatly diminished. Label performance directly influences the performance of your total RFID solution.

Selecting the Right Supplier

The right RFID supplier can help you select the right RFID labels. A good supplier will assess your solution needs in several areas, including:

- Label solution. Your application will inform the proper material and adhesive as well as the type of label and tag that could withstand exposure to extremes of the environment.

- Right chip selection. The application and enterprise needs will determine whether a standard or high-memory tag will work best. You must also consider the requirements needed to achieve the appropriate level of privacy protection and encryption for your organization and industry.

- Application environment. An analysis of your actual environment will reveal whether it is RF friendly and if your labeling surface involves special requirements. For example, you will be able to confirm which reader and antenna can be used, how and when will the RFID inlay be read and what level of read accuracy is expected.

The business application itself will also dictate whether or not you need a general purpose, advanced or specialty RFID label. For example:

- General purpose labels, which are typically made of paper or synthetic materials that adhere to non-metallic surfaces, plastics or corrugate, are commonly used for case, pallet and cross-docking applications in distribution, logistics and warehouse operations. They may also be used for work-in-process or security and product lifecycle tagging in manufacturing environments or for patient records management in healthcare environments.

- Advanced labels, which offer a higher level of read performance, are typically better for retail, healthcare and manufacturing applications where longer read ranges are required.

- Specialty labels, such as Silverline on-metal labels, are recommended for asset tagging on metal surfaces or for liquid-filled containers. These are especially beneficial for tracking manufacturing tools and parts or chemical drums as well as healthcare supplies such as oxygen canisters, wheelchairs, IV pumps and more. On-metal labels are also best for IT asset management, as they can affix easily to mobile computers, printers, antennas and infrastructure components.

Article by: Zebra Technologies