Now more than ever before our countries are connected globally via an intricate network of logistics and supply chains. Based on studies the full visibility of the supply chain and the optimization of inventories are the key initiatives among the companies. As the demand on our logistics infrastructure increases, companies are being pushed to find ways to improve their efficiency.

Common Challenges of Logistics & Inventory

Whether you are trying to locate a package within a warehouse, as it travels to the next supplier, or even as it arrives into the next country UHF RFID technology will give you the full visibility throughout the whole supply chain. As an engineering company at heart, Confidex designed products for optimum RF performance and cost efficiency on materials commonly used in disposable packaging.

Designed for Logistics

Each label has been carefully designed for optimum RF performance in a specific use-case. With RFID tags for disposable packaging it is important to optimize the cost of the product while not sacrificing the reliability of the reading large amount of tags. The size of the label is often driven by the existing standardized barcode label layouts and therefore we offer our labels with various sizes to meet the dimensional requirements.

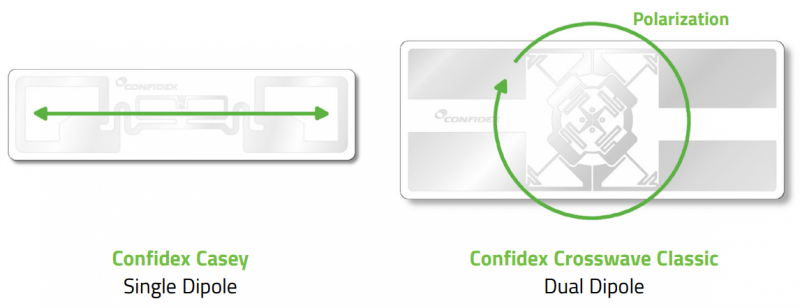

Different use-cases might require different features from the product. For example, high performing single dipole designs (Casey) are optimum for standard inbound/outbound applications especially with a known asset orientation. Omni-directional dual dipole designs (Crosswave) offers increased flexibility with linear reader antennas or RTLS systems as they can be read in any orientation.

The introduction of our all-surface label (Ferrowave) allows for the ultimate flexibility in tagging a wide variety of materials with a single label, including metals and liquids. Lastly, we continue our company wide legacy of the importance in material sustainability with our plastic-free label design (Leaf).

Personalised

All of our labels are RFID printer-friendly via thermal transfer ribbon method and offer ample space to capture all of the important visual printing required. Confidex can deliver labels also pre-printed and encoded in case requested.

Attachment Methods

“Slap and ship” – it’s as simple as that. Our adhesives have been carefully selected based on reliability and cost-efficiency to function best on the materials most utilized in the industry for packaging. Labels are compliant with all major applicator brands.

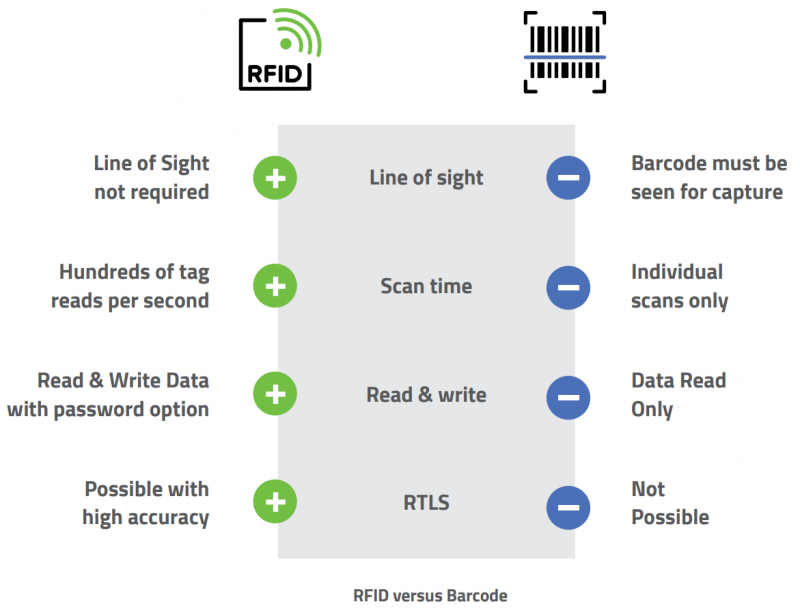

RFID versus Barcode

Traditionally the logistics of disposable packaging relies on barcode labels. There are some significant differences between the technologies that should be considered when optimizing supply chain.

Why polarization matters?

Like with reader antennas there are also different tag antenna designs. Most common shipping labels use single dipole design that is compatible with circular polarized reader antennas, such as Confidex Casey. Reader and tag antenna orientation has to always match for best performance. For applications with linear reader antenna and unknown asset orientation it is recommended to use dual-dipole design, such as Confidex Crosswave product line. This ensures labels is always readable no matter what is the reader antenna orientation.

Article Credit – https://www.confidex.com/technology-insights/rfid-for-disposable-packaging/